The popularity of artificial turf has soared in recent years, transforming the way sports fields are built and maintained across the globe. From local recreational fields to international stadiums, synthetic turf has become the go-to solution for consistent performance, durability, and year-round usability.

If you’re planning to build a sports field or upgrade an existing one, understanding the artificial turf construction process is essential. This guide walks you through every stage—from planning and design to installation and long-term care—ensuring your artificial sports surface performs at its best for years to come.

Why Artificial Turf for Sports Fields?

Artificial turf offers numerous advantages over natural grass, making it a preferred choice for schools, municipalities, sports clubs, and professional facilities. Here are some of the primary benefits:

1. Durability

Synthetic turf is engineered to withstand heavy foot traffic, extreme weather conditions, and frequent use. It can accommodate multiple sports and events without deteriorating, unlike natural grass, which wears down quickly.

2. Low Maintenance

Say goodbye to mowing, watering, fertilizing, and reseeding. Artificial turf dramatically reduces maintenance requirements, lowering costs and labor over the life of the field.

3. Year-Round Usability

Artificial fields stay playable in virtually any weather. Rain or shine, they provide a consistent surface with excellent drainage and minimal downtime.

4. Player Safety and Performance

Modern turf systems are designed to mimic the look and feel of natural grass while offering enhanced shock absorption, traction, and surface stability—reducing the risk of injuries.

Applications of Artificial Turf

Artificial turf is suitable for a variety of sports and activities, including:

- Soccer (FIFA-certified turf systems)

- American Football and Rugby

- Field Hockey and Lacrosse

- Baseball and Softball

- Multi-sport recreational fields

- Running tracks and training facilities

Step-by-Step Artificial Turf Construction Process

Constructing a synthetic turf sports field is a multi-phase process that requires proper planning, engineering, and skilled installation. Here’s a detailed breakdown:

1. Site Assessment and Design

Before breaking ground, conduct a comprehensive site survey. Evaluate soil type, slope, existing drainage systems, and intended field usage. Work with a qualified sports field designer to create a detailed blueprint addressing:

- Drainage layout

- Base construction

- Turf system selection

- Sport-specific markings

- Lighting and fencing(if applicable)

2. Excavation and Grading

The site is excavated to a depth that allows for drainage systems, base layers, and turf. Typically, 8–12 inches of soil is removed. The subgrade is then compacted and graded to ensure an even surface and proper slope for water runoff.

3. Drainage System Installation

A robust drainage system is critical. Most fields use a network of perforated pipes laid in trenches and surrounded by clean gravel. The system efficiently directs water away from the field, preventing puddles and turf degradation.

4. Base Layer Construction

A crushed stone or gravel base (typically 4–6 inches deep) is laid over the drainage system. It’s compacted and laser-graded to form a stable, permeable foundation that supports the turf and provides flatness.

5. Shock Pad Installation (Optional)

A shock pad layer is often placed between the base and the turf to reduce impact injuries and improve performance. These pads are especially important for high-contact sports like football and rugby.

6. Artificial Turf Installation

Turf rolls are laid out and aligned. Seams are bonded using adhesives or special seam tape to create a unified surface. Turf fibers are brushed up to stand vertically, creating a more realistic grass appearance.

7. Infill Application

Infill materials are spread across the turf to add ballast, provide cushioning, and support turf fibers. Common infill types include:

- Silica sand

- Crumb rubber (recycled rubber granules)

- Thermoplastic elastomers (TPE)

- Organic infills (e.g., cork, coconut fibers)

The infill layer improves performance, absorbs impact, and prevents premature wear.

8. Grooming and Final Inspection

The field is groomed using specialized equipment to level the infill and ensure a consistent playing surface. A final inspection verifies seam integrity, turf quality, drainage function, and compliance with safety standards.

Key Factors to Consider When Building a Synthetic Turf Field

1. Sport Requirements

Different sports demand different turf pile heights, infill depths, and shock absorption properties. Always consult guidelines from governing bodies such as:

- FIFA for soccer

- World Rugby

- IAAF for athletic tracks

- NCAA and NFHS standards

2. Turf Material and Pile Height

Choose turf made from UV-stabilized polyethylene or polypropylene with pile heights between 40–60mm, depending on the sport. Turf density and backing material also impact field quality.

3. Climate and Location

Consider environmental factors like rainfall, temperature fluctuations, and freeze-thaw cycles. Drainage design and infill selection should be adapted accordingly.

4. Field Usage

Determine whether the field will be used for a single sport or multiple activities. Multi-use fields may require customizable line markings or mobile goalposts.

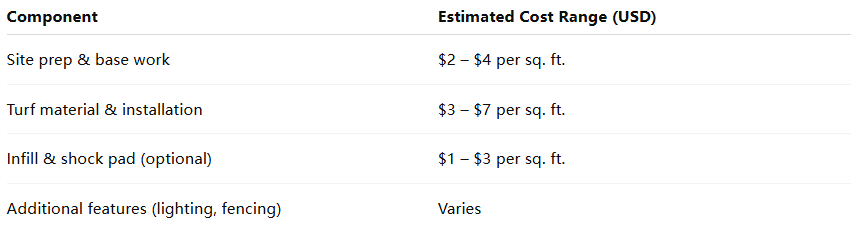

Cost of Artificial Turf Construction

Artificial turf construction typically ranges from $5 to $12 per square foot, depending on materials, location, and complexity. Here’s a general breakdown:

While the upfront investment is higher than natural grass, synthetic turf pays off through lower maintenance, extended usage, and greater revenue opportunities for rental fields.

Maintenance Tips for Artificial Sports Fields

Although maintenance is minimal compared to natural grass, it is essential to prolong the field’s life and performance:

- Regular Grooming: Keep infill evenly distributed and turf fibers upright.

- Surface Cleaning: Remove debris, litter, and organic matter to prevent microbial growth.

- Infill Top-Ups: Replenish infill every 1–2 years, especially in high-traffic zones.

- Seam Inspection: Monitor joints and edges for separation or wear.

- Annual Deep Cleaning: Use professional equipment to remove compacted dirt and restore playability.

Conclusion

Artificial turf construction is a smart investment for sports facilities looking to maximize field usage, minimize maintenance, and ensure consistent performance in all weather conditions. Whether you’re building a community soccer field, a school athletic complex, or a professional stadium, the key to success lies in choosing the right turf system and working with experienced installers.

By following best practices in design, installation, and maintenance, your artificial sports field can remain in top condition for over 10–15 years—delivering a high return on investment and an outstanding experience for athletes and spectators alike.